Nozzles for Pressure Washers

A common question we gat asked by customers is “ If I put a smaller nozzle in my lance will it give me more pressure “ and the answer is pretty straight forward.

Every pump is designed to produce a specific pressure at a certain flow of water. If you fit a nozzle which is too small and causes the machine to over pressure then either the machine will not function correctly or you could cause the machines motor to overheat and even cause long term damage. Basically you want the right nozzle for the right machine, if you require more pressure then you should be considering a different machine.

The nozzles themselves are often the most overlooked component on a high pressure washer, but they have a vital role to play in how effective the machine is. If the nozzle is too big then not enough pressure will be created and if it is too small then the aforementioned problems can occur.

In its simplest form the nozzle is just a specific sized orifice that when water is forced through pressure is created. Once you know the correct size of nozzle you need then you can choose at which angle you require the water to spray out, the most common nozzle will spread the water over a 15 degree pattern, but other choices ranging between 0 and 40 degrees are available. If you have a chemical injector on your machine you may also need a low pressure nozzle in order to allow the pressure drop required for the venture to operate.

There are also different ways in which the nozzle connects to the lance, such as quick release - which allows the user to quickly change between variants of nozzle or screw in nozzles commonly known as MEG nozzles - which are physically screwed on to the lance in a fixed position. Karcher machines in particular use a “ T “ jet system where the nozzle can be changed by removing a hand screw coupling.

Turbo nozzles are another type of nozzle which can produce great cleaning results for certain applications. The standard turbo nozzle is basically a “ pencil “ jet or zero degree nozzle that spins round in a circle at either 15 or 25 degrees. All the user will see is a circular pattern due to the speed at which the nozzle rotates. Turbo nozzles create a dual hammer and cutting effect making them great tools for really stubborn cleaning tasks, they are very popular for drive cleaning and agricultural tasks but obviously due to their aggressiveness would not be suitable for car cleaning or paintwork in general ( unless you want to strip the paint off! ).

Drain nozzles or sewer nozzles are another attachment for use with pressure washers, although there are different types available, most drain nozzles will have one forward facing jet and three or more rear facing jets. The purpose of the forward facing jet is to cut a way through the blockage while the rear facing jets purpose is to propel the hose through the drain in question and to flush any debris away. Drain jetting nozzles can be used with any pressure washer but are much more successful when used with high flow output machines. Most purpose built drain jetting machines will be engine driven units capable of 40 litres per minute or more.

General info regarding high pressure nozzles

Nozzles go up in size – a 05 nozzle has a bigger orifice than a 04 nozzle.

Nozzles generally have two figures of importance. A 1505 nozzle will tell you that the nozzle will spread the water over a 15 degree fan pattern and the 05 is the size of the orifice itself.

Increasing the size of a nozzle will reduce the pressure produced from the pump but will not effect the flow of water, this is the ideal way of lowering your pressure without adjusting your unloader valve especially if the machine does not have a pressure reducer tap.

Decreasing the nozzle size can will increase pressure but it will also reduce the flow, with a flow sensitive unloader this may cause the unloader to enter bypass mode which can usually be identified by “ surging “ symptoms or the pressure repeatedly going up and down, with a trapped pressure unloader the valve will bypass the excess water.

If you believe that your machine isn’t quite producing the pressure it used to then your first item to check should be the nozzle. Over a period of time and use the hole size in the nozzle will get bigger and it is surprising how much of a difference to pressure only a slight enlargement can make.

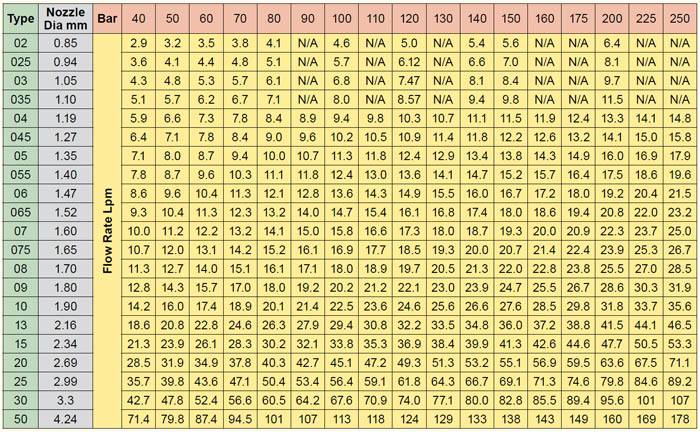

If you already know the working pressure and flow that your pump should be producing then it is fairly simple to find the correct nozzle for your machine. Please see the chart below.

.

Choose Britclean for Industrial Pressure Washer Nozzles

If you are still unsure of what nozzles to use with your pressure washers, feel free to contact us today for more information